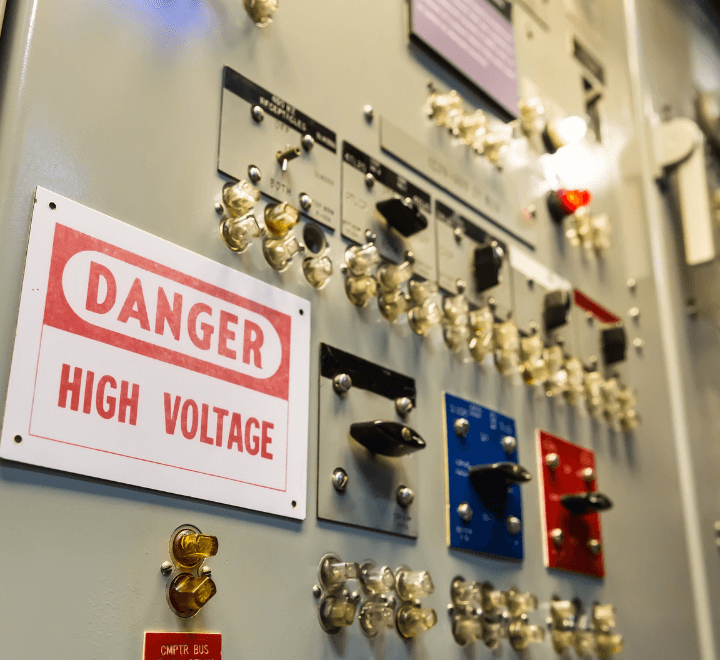

Control panels serve as the nerve center of industrial processes, enabling seamless control, monitoring, and automation. What sets CID’s offerings apart is the ability to create tailor-made solutions that precisely align with the unique needs of each client. Whether it’s a complex manufacturing facility, a critical infrastructure project, or a specialized process, CID’s custom control panels are engineered to provide optimal performance and efficiency.

Key Features of CID’s Custom Control Panels:

- Precision Engineering: CID’s control panels are crafted with meticulous precision. From the selection of components to the layout and wiring, every aspect is fine-tuned to meet the specific requirements of the application. Precision engineering ensures reliability, efficiency, and longevity.

- Beautiful Design: No two industrial processes are identical, and CID understands this diversity. Each control panel is designed from the ground up, considering the unique challenges and demands of the system it will control. Bespoke design ensures that the control panel seamlessly integrates into the existing infrastructure.

- Advanced Electrical Components: CID Associates sources and utilizes state-of-the-art electrical components for its custom panels. This includes programmable logic controllers (PLCs), human-machine interface (HMI) screens, variable frequency drives (VFDs), and other cutting-edge components that form the backbone of modern industrial automation.

- Pneumatic System Integration: In addition to electrical components, CID excels in integrating pneumatic systems into its control panels. This capability is particularly crucial in industries where precise control over air pressure and flow is essential, such as in manufacturing and certain types of machinery.

- Compliance and Safety: CID’s commitment to excellence extends to compliance with industry standards and safety regulations. Custom control panels are designed and manufactured with adherence to relevant codes, ensuring not only optimal functionality but also the highest levels of safety for operators and the surrounding environment.

Applications of CID’s Custom Control Panels:

- Manufacturing and Assembly Lines: CID’s control panels find extensive application in manufacturing and assembly processes, where precise control is crucial for maintaining efficiency and product quality.

- Water and Wastewater Treatment: Custom control panels play a pivotal role in water and wastewater treatment plants, where they facilitate the automation of complex processes, ensuring optimal resource utilization and environmental compliance.

- Energy and Utilities: From power distribution to monitoring and controlling energy infrastructure, CID’s control panels are deployed in the energy and utilities sector, contributing to the reliability and efficiency of operations.

- Food and Beverage Industry: In the food and beverage sector, where hygiene standards and process control are paramount, custom control panels ensure seamless operations and compliance with industry regulations.

- Pharmaceutical and Chemical Processing: CID’s panels play a critical role in pharmaceutical and chemical processing, where precision control is necessary to maintain product quality and safety.

Innovative Approaches to Manufacturing:

CID Associates employs innovative approaches to the manufacturing of custom control panels, ensuring that the end product not only meets but exceeds client expectations.

- Collaborative Design Process: CID’s engineers engage in a collaborative design process with clients. This collaborative approach ensures that the final control panel is not only technically superior but also aligns seamlessly with the client’s operational needs and preferences.

- Modular Construction: Taking advantage of modular construction techniques, CID streamlines the manufacturing process. This not only expedites delivery but also allows for scalability and ease of future modifications.

- Integrated Testing: Before a custom control panel leaves the CID facility, it undergoes rigorous testing. This integrated testing process ensures that each component functions as intended and that the panel as a whole meets the highest standards of performance and reliability.

Contact CID Associates for Your Custom Control Panel Needs:

CID Associates is located at 29 Ekastown Road (Route 228), Sarver, PA 16054. If you are considering a custom electrical or pneumatic control panel for your industrial processes, CID’s dedicated team is ready to assist you:

- Phone: (723) 353-0300

- Fax: (723) 353-0308

- Email: sales@cidbuildings.com

Invest in precision, reliability, and innovation with CID’s custom electrical and pneumatic control panels. Your operations deserve nothing less than the exceptional craftsmanship and expertise that CID Associates brings to the table.